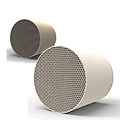

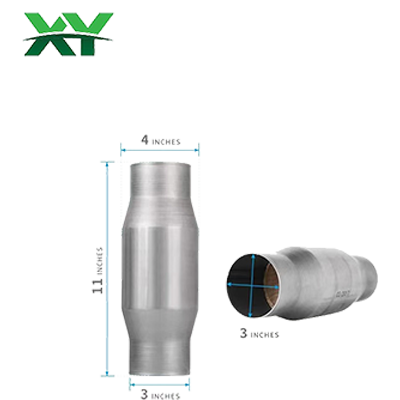

III. Catalyst Materials 1. Substrate: Cordierite (low thermal expansion, strong thermal shock resistance). Gasoline engine TWC honeycomb matrix: Silicon carbide (SiC). High thermal conductivity, high strength. High-temperature diesel catalyst/industrial exhaust gas. The substrate structure typically features honeycomb or sheet-like corrugated channels to reduce backpressure and provide a large surface area.

2. Washcoat • Primarily composed of γ-Al₂O₃, CeO₂-ZrO₂, and TiO₂ • Functions: • Increases specific surface area (providing hundreds of square meters/g) • Immobilizes precious metals • Provides oxygen storage and release capabilities • Typically 10–30 μm thick, with a microporous structure ensuring adequate contact between gas and metal

3. Precious Metal Catalytic Layer • Platinum (Pt): Oxidizes CO and HC • Palladium (Pd): Oxidizes HC and CO • Rhodium (Rh): Reduces NOₓ Precious metals are formed into nanoparticles through impregnation, drying, and calcination, and then dispersed within the pores of the washcoat, ensuring high activity and durability.

IV. Application Scenarios 1. Automotive Exhaust Purification • Gasoline Vehicle TWC: Simultaneously oxidizes CO/HC and reduces NOₓ • Diesel Vehicle DOC + DPF Combination: Oxidizes unburned hydrocarbons and assists in particulate filter regeneration • SCR + DOC: Partial NOₓ is further degraded by a reducing agent (NH₃ or urea) 2. Industrial Waste Gas Treatment • VOC Catalytic Combustion • CO and NOₓ Treatment • Chemical Synthesis Reaction Optimization In industrial systems, the carrier is typically made of high-thermal-conductivity silicon carbide or alumina. Precious metals can be evenly distributed through the coating to ensure efficient conversion even at high exhaust temperatures.

V. Aging and Improvements • Aging Issues: Precious metal sintering, reduced coating porosity, and decreased oxygen storage capacity • Improvement Measures: • Stabilized coating (CeZr solid solution, La₂O₃ doping) • Nanodispersion technology to ensure high dispersion of precious metals • High thermal conductivity carrier materials to reduce local overheating

VI. Conclusion: Catalytic converters and three-way catalytic converters achieve efficient exhaust gas purification through honeycomb-structured carriers, optimized coatings, and precious metal dispersion technology. Their performance directly determines the effectiveness of emission control in automotive and industrial exhaust treatment.