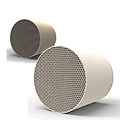

The catalyst carrier is mainly used in the cars and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, in order to achieve the global emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.

1. Automotive Exhaust Purification

• Serves as the core component of three-way catalytic converters.

• Catalytically oxidizes and reduces harmful gases such as CO, HC, and NOₓ, achieving environmental emission standards.

2. Industrial Waste Gas Treatment

• Treats pollutants such as VOCs (volatile organic compounds), NOₓ, and CO generated in industry.

• Used in waste gas purification systems for the chemical, coating, pharmaceutical, and electronics industries.

3. Denitrification (SCR) Systems

• Utilizes selective catalytic reduction (SCR) technology in coal-fired power plants, cement plants, and boilers to remove nitrogen oxides.

• Typically carries active components such as V₂O₅–WO₃/TiO₂.

4. Municipal Waste Incineration Flue Gas Purification

• Used for high-temperature flue gas purification and dioxin emission control. 5. Chemical Catalytic Reaction Supports

• Catalyst supports used in industrial reactions such as ammonia synthesis, methanol to olefins (MTO), and alkane dehydrogenation.