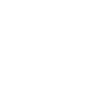

Ceramic catalyst carriers are one of the most fundamental components in automotive exhaust purification and industrial waste gas treatment systems. They do not directly participate in chemical reactions, but rather provide a supporting structure, high specific surface area, and thermally stable environment for catalysts (especially precious metal catalysts), enabling reactant gases to fully contact and react efficiently with the active metal. In a typical catalytic system, the catalyst consists of three parts: Ceramic carrier → Washcoat → Precious metal active component. The ceramic carrier provides mechanical and thermal stability, the washcoat provides a porous adsorption interface, and the precious metal layer is the active center for the actual oxidation and reduction reactions. These three components together determine the catalyst's activity, lifespan, and anti-aging properties.