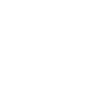

Honeycomb Structure and Gas Distribution Ceramic supports in automotive and industrial catalytic systems mostly adopt a honeycomb structure (monolith), with hundreds to thousands of parallel channels (typically 200–600 CPSI). This structure has the following characteristics: • Uniform gas flow: ensures low pressure drop and stable flow rate when exhaust gas passes through the catalyst layer; • Large specific surface area: provides sufficient contact interface for the reaction; • High mechanical strength: can withstand the high temperature and vibration environment of engines or industrial equipment. When pollutant-containing gases (such as CO, HC, NOₓ, or VOCs) pass through the channels of the catalyst support, the reactant gas molecules diffuse to the coating and noble metal surface, are adsorbed and participate in the reaction, and are ultimately converted into harmless products such as CO₂, H₂O, and N₂. ⸻2. Overview of Working Mechanism The ceramic support primarily functions in the following ways: • Support and Distribution: Ensuring uniform distribution of the coating and precious metals, providing stable geometric support; • Thermal Stability and Insulation: Ensuring the catalyst does not melt or deform at 800–1100 °C; • Chemical Inertness: Preventing side reactions with reactant gases or precious metals; Heat Transfer and Diffusion Properties: Helping to maintain temperature equilibrium in the reaction zone.