1. Material Selection and Carrier Preparation

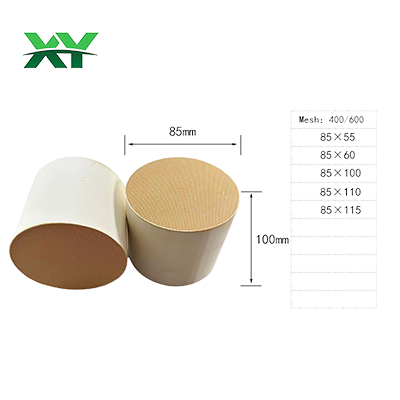

• Ceramic carriers are typically made of alumina, titania, or zirconia, sintered into a honeycomb or plate-like structure. Uniform pores ensure good dispersion of precious metals.

• Metal carrier: Made of stainless steel or nickel-based alloy, the metal honeycomb structure provides high toughness and thermal conductivity.

Key Requirements:

• Strictly controlled porosity and surface area to ensure catalyst reactivity;

• The carrier shape and size must be perfectly matched to the customer's exhaust system.

2. Precious Metal Coating

• Commonly used precious metals: Platinum (Pt), Palladium (Pd), Rhodium (Rh)

• Coating Methods:

1. Impregnation: Immerse the carrier in a precious metal solution for uniform adsorption;

2. Spraying: Suitable for metal catalysts, controls coating thickness and uniformity;

3. Drying and calcination: Ensures strong adhesion of the precious metal and stability of the active components.

Standard Requirements:

• Precise control of precious metal content (ppm or g/L level);

• Uniform distribution to avoid local over- or under-concentration;

• Strict control of sintering temperature and time to ensure high-temperature resistance.

3. Catalytic Converter Assembly

• Secure the coated catalyst in the housing to ensure uniform airflow through the catalyst layer; • Install high-temperature, corrosion-resistant gaskets to ensure leak-free interfaces;

• Test pressure drop and exhaust gas purification efficiency to ensure compliance with customer and regulatory requirements.