Factory – Manufacturer of High-Performance Ceramic Catalysts, Metal Catalysts, and Catalytic Converters In today's world of increasingly stringent global automotive emission standards, automotive exhaust purification technology has become crucial for driving environmental protection and sustainable development. As a professional manufacturer specializing in the research and development and production of ceramic catalysts, metal catalysts, and catalytic converters, we are committed to providing efficient, stable, and reliable solutions for the global automotive and industrial exhaust purification market.

I. Our Products

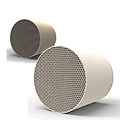

1. Ceramic Catalysts

• Features: Utilizes a ceramic carrier with high high-temperature resistance, uniform pore structure, and uniform dispersion of precious metals.

• Advantages:

• High temperature resistance and strong chemical stability

• Long service life, suitable for high-speed and long-term operation

• Applications: Highway long-distance buses, diesel engine DPF systems, industrial exhaust purification, etc.

2. Metal Catalysts

• Features: Utilizes a stainless steel or nickel-based alloy carrier, with a surface coating of precious metals, offering good toughness and rapid thermal conductivity. • Advantages:

• High vibration resistance, adaptable to engine vibration

• Rapidly reaches operating temperature, excellent cold start emission control

• Application scenarios: Passenger cars, hybrid vehicles, low-temperature emission control for small vehicles

3. Catalytic Converter

• Features: Integrates ceramic or metal catalysts, employs a high-precision shell design to ensure uniform airflow through the catalyst layer.

• Advantages:

• Highly efficient purification of harmful gases such as CO, HC, and NOx

• Supports customization for various vehicle models, balancing durability and environmental performance

• Application scenarios: From traditional gasoline vehicles to new energy hybrid vehicles, covering various engine specifications

⸻ II. Our Technological Advantages

1. Independent R&D Capability

• Possesses a complete catalyst formulation and production process R&D system

• Can customize catalysts of different specifications and with different carrier materials according to customer needs

2. Advanced Production Equipment

• High-temperature sintering furnace, precision coating equipment, automated assembly line

• Ensures the quality stability of ceramic and metal catalysts

3. Strict Quality Control

• Full-process testing: Raw materials → Carrier sintering → Precious metal coating → Finished product testing

• Each batch of products passes multiple tests, including high temperature resistance, vibration, and emission efficiency.

4. Environmental Protection and Sustainability

• High-efficiency catalysts can reduce harmful emissions from vehicle exhaust

• Used catalysts can be recycled for precious metals, achieving resource recycling. ⸻ III. Our Commitment As a professional catalyst manufacturer, we adhere to the principles of quality first, innovation-driven development, and customer supremacy, providing customers with:

• High-performance, highly reliable catalyst products

• Customized design solutions to meet the needs of different vehicle models and industrial equipment

• Comprehensive technical support and after-sales service

We are committed to promoting automotive exhaust treatment and environmental protection through advanced catalytic technology, contributing to the construction of green transportation and sustainable industry.