The Role and Mechanism of Metal Catalysts in the Automotive and Industrial Fields

I. Overview

Metal catalysts are a class of catalytic materials with metals or metal oxides as the main active components, widely used in industrial fields such as automotive exhaust purification, chemical reactions, petroleum refining, and waste gas treatment. Their main function is to provide the active surface required for the reaction to proceed efficiently.

In the automotive field, metal catalysts are commonly used in three-way catalytic converters (TWC) and diesel oxidation catalytic converters (DOC) in hydrogenation desulfurization, ammonia oxidation, and waste gas incineration units.

II. Working Principle of Metal Catalysts

The working mechanism of metal catalysts mainly relies on the adsorption-reaction-desorption cycle. This process can be divided into the following stages:

1. At the adsorption site, weakened chemical bonds are formed.

2. For example, CO is oxidized to CO₂, and NO is reduced to N₂. 3. Product Desorption Stage: The reaction products desorb at a low energy level on the catalyst surface, releasing active sites and providing conditions for the next round of reaction.

China is consumed.

⸻ III. Structure and Composition of Metal Catalysts

Metal catalysts typically consist of three parts:

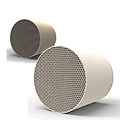

1. Matrix (Support): Provides mechanical strength and specific surface area. Automotive catalysts often use honeycomb metal or ceramic supports, such as stainless steel corrugated plates, cordierite, and silicon carbide (SiC).

2. Transition Layer (Coating, Washcoat): Provides an adhesion surface for the precious metal. High specific surface area materials such as alumina (Al₂O₃), titanium dioxide (TiO₂), and zirconium oxide (ZrO₂) are commonly used, and CeO₂ and La₂O₃ are often doped to improve oxygen storage and resistance to thermal aging.

3. Different Reaction Functions—

• Platinum (Pt): Excels in oxidation reactions, promoting the oxidation of CO and HC to CO₂ and H₂O;

• Palladium (Pd): Exhibits superior hydrocarbon oxidation performance at low temperatures;

• Rhodium (Rh): Primarily used in the reduction of NOx, converting NO and NO₂ to N₂.

IV. Noble Metal Coating and Distribution Processes

The performance of metal catalysts largely depends on the coating process and uniformity of the noble metals. Common coating methods include:

1. Impregnation: Immersing the support in a noble metal salt solution, followed by adsorption, drying, and calcination to form an active layer. Suitable for mass catalyst production.

2. Spray Coating: Creating a uniform thin film, commonly used for stainless steel-based supports.

3. Sol-Gel Method: Utilizing the hydrolysis of organometallic precursors to form a gel layer, dispersing the noble metals in a nanoscale structure, enhancing adhesion and thermal stability. The coating thickness is generally controlled within the range of 20–150 µm to balance catalytic activity and airflow resistance.

Temperature is maintained at 450–600 ℃ to ensure a strong bond between the precious metal and the oxide support.

⸻ V. Applications in the Automotive Industry

In automotive exhaust purification systems, metal catalysts play a crucial role:

• Three-way catalytic converter (TWC): Simultaneously achieves three reactions: CO oxidation, HC oxidation, and NOx reduction. Typical reactions are as follows:

• 2CO + O₂ → 2CO₂

• CₙHₘ + (n + m/4)O₂ → nCO₂ + m/2H₂O

• 2NO → N₂ + O₂

• Diesel oxidation catalytic converter (DOC): Primarily used to oxidize CO and HC in diesel engine emissions, while simultaneously promoting the conversion of NO to NO₂, providing oxidation conditions for the regeneration of the subsequent DPF (particulate filter).

Exhaust temperatures above 1000℃ are suitable for vehicles operating at high speeds or under high loads.

⸻ VI. Industrial Applications

In industrial production, metal catalysts are widely used in:

• Organic synthesis: such as hydrogenation, dehydrogenation, isomerization, oxidation reactions, etc. (Ni, Pt, and Pd catalysts are commonly used);

• Petroleum refining and desulfurization: used to reduce sulfides to H₂S, reducing fuel pollution;

• VOCs

• Ammonia oxidation: Pt-Rh network catalysts are used to produce nitric acid;

• Hydrogen production and fuel cells: promoting hydrogen oxidation or electrochemical reactions through precious metals. ⸻ VII. Performance Optimization and Development Trends

With increasingly stringent emission standards, research on metal catalysts mainly focuses on:

1. Reducing the loading of precious metals and high dispersion technology;

2. Pd-Pt, Pt-Rh composite systems;

3. Development of high-temperature anti-sintering materials (such as Ce-Zr solid solution oxides);

4. New plasma-assisted catalysis and electrocatalysis technologies;

5. Recyclable and regenerable catalyst systems to reduce the cost of precious metals.

⸻ VIII. Conclusion

Metal catalysts are one of the core materials for modern automotive emission control and clean industrial production. Through research on support structure, precious metals…

With the rapid development of new energy vehicles, hydrogen energy, and green manufacturing, metal catalysts will continue to play an irreplaceable role in energy conservation, emission reduction, and sustainable industrialization. The Role and Mechanism of Metal Catalysts in the Automotive and Industrial Fields

I. Overview

Metal catalysts are a class of catalytic materials with metals or metal oxides as the main active components, widely used in automotive exhaust purification, chemical reactions, petroleum refining, and waste gas treatment, among other industrial fields. Its main function is to provide the active sites required for the reaction to proceed efficiently.

In the automotive field, metal catalysts are commonly used in three-way catalytic converters (TWC) and diesel oxidation catalytic converters (DOC) in hydrogenation desulfurization, ammonia oxidation, and waste gas incineration units.

⸻ II. Working Principle of Metal Catalysts The working mechanism of metal catalysts mainly relies on the adsorption-reaction-desorption cycle. This process can be divided into the following stages:

1. At the adsorption site, a weakened chemical bond is formed.

2. For example, CO is oxidized to CO₂, and NO is reduced to N₂.

3. Product desorption stage: The reaction products desorb at a low energy state on the catalyst surface, thereby releasing active sites and providing conditions for the next round of reaction. By continuously repeating this cycle, the catalyst achieves a significant increase in the reaction rate, while theoretically, it is not consumed in the reaction. III. Structure and Composition of Metal Catalysts

Metal catalysts typically consist of three parts:

1. Automotive catalysts often use honeycomb-shaped metal or ceramic supports, such as stainless steel corrugated plates, cordierite, and silicon carbide (SiC).

2. Transition layer (coating, washcoat): This provides an adhesion surface for the precious metal. High specific surface area materials such as alumina (Al₂O₃), titanium dioxide (TiO₂), and zirconium oxide (ZrO₂) are commonly used, and CeO₂ and La₂O₃ are often doped to improve oxygen storage and resistance to thermal aging. 3. Different Reaction Functions—

• Platinum (Pt): Excellent at oxidation reactions, promoting the oxidation of CO and HC to CO₂ and H₂O;

• Palladium (Pd): Exhibits superior hydrocarbon oxidation performance at low temperatures;

• Rhodium (Rh): Primarily used for the reduction of NOx, converting NO and NO₂ to N₂.

⸻ IV. Noble Metal Coating and Distribution Processes The performance of metal catalysts largely depends on the coating process and uniformity of the noble metal. Common coating methods include:

1. Impregnation: Immersing the support in a noble metal salt solution, followed by adsorption, drying, and calcination to form an active layer. Suitable for mass catalyst production.

2. Spray Coating: Creating a uniform thin film, commonly used for stainless steel-based supports.

3. Sol-Gel Method: This method utilizes the hydrolysis of metal-organic precursors to form a gel layer, dispersing noble metals within a nanoscale structure, thus enhancing adhesion and thermal stability.

Coating thickness is typically controlled within the range of 20–150 µm to balance catalytic activity and airflow resistance.

Temperature is maintained at 450–600 ℃ to ensure a strong bond between the noble metal and the oxide support.

⸻ V. Applications in the Automotive Industry

In automotive exhaust purification systems, metal catalysts play a crucial role:

• Three-way catalytic converter (TWC): Simultaneously achieves CO oxidation, HC oxidation, and NOx reduction. Typical reactions are as follows:

• 2CO + O₂ → 2CO₂

• CₙHₘ + (n + m/4)O₂ → nCO₂ + m/2H₂O

• 2NO → N₂ + O₂

• Diesel Oxidation Catalyst (DOC): Primarily used to oxidize CO and HC in diesel engine emissions, while simultaneously promoting the conversion of NO to NO₂, providing oxidation conditions for the regeneration of the subsequent DPF (Diesel Particulate Filter).

Exhaust temperatures above 1000℃, suitable for vehicles operating at high speeds or under high loads.

VI. Industrial Applications

In industrial production, metal catalysts are widely used in:

• Organic synthesis: such as hydrogenation, dehydrogenation, isomerization, oxidation reactions, etc. (Ni, Pt, and Pd catalysts are commonly used);

• Petroleum refining and desulfurization: used to reduce sulfides to H₂S, reducing fuel pollution;

• VOCs

• Ammonia oxidation: Pt-Rh network catalysts are used to produce nitric acid;

• Hydrogen production and fuel cells: using noble metals to promote hydrogen oxidation or electrochemical reactions.

⸻ VII. Performance Optimization and Development Trends

With increasingly stringent emission standards, research on metal catalysts mainly focuses on:

1. Reducing the loading of precious metals and high dispersion technology;

2. Pd-Pt, Pt-Rh composite systems;

3. Development of high-temperature anti-sintering materials (such as Ce-Zr solid solution oxides);

4. New plasma-assisted catalysis and electrocatalysis technologies;

5. Recyclable and regenerable catalyst systems to reduce the cost of precious metals.

⸻ VIII. Conclusion

Metal catalysts are one of the core materials for modern automotive emission control and clean industrial production. Through improvements in support structure and precious metal content,

With the rapid development of new energy vehicles, hydrogen energy, and green manufacturing, metal catalysts will continue to play an irreplaceable role in energy conservation, emission reduction, and sustainable industrialization.