The working principles of DOC, DPF, and SCR.

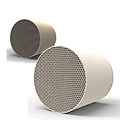

1. DOC (Diesel Oxidation Catalyst) Working Principle • Main function: Oxidizes CO (carbon monoxide), HC (unburned hydrocarbons), and some NO (nitrogen oxides) in the exhaust gas. • Chemical reactions: • CO + ½ O₂ → CO₂ • HC + O₂ → CO₂ + H₂O • DOC is usually used as a pre-stage to DPF and SCR to increase NO₂ concentration (which helps with particulate matter oxidation in DPF and reduction reactions in SCR). Material • Carrier material: • Ceramic honeycomb (Cordierite) or metal honeycomb (stamped from stainless steel sheets). • Coating layer: • Precious metal catalyst: mainly platinum (Pt) or platinum + palladium (Pd), used for oxidation reactions. • The carrier coating usually contains aluminum oxide (Al₂O₃) to increase the surface area. — 2. DPF (Diesel Particulate Filter) Working Principle • Main function: Filters particulate matter (PM, mainly black smoke and carbon particles) from the exhaust gas. • Mechanism: 1. Exhaust gas passes through the honeycomb ceramic channels, and particles are blocked on the channel walls. 2. The captured carbon particles are oxidized through regeneration: • Passive regeneration: Uses NO₂ generated by DOC to slowly oxidize PM at normal temperature. • Active regeneration: Increases exhaust temperature (fuel injection or electric heating) to accelerate PM oxidation. Material • Carrier material: • Ceramic: Aluminum silicate (Cordierite) or silicon carbide (SiC). • Cordierite: Good thermal shock performance, low cost, suitable for low-speed urban conditions. • Silicon carbide: High temperature strength, suitable for high-speed and high-load conditions, good resistance to clogging. • Coating layer: • A light coating to improve oxidation efficiency, such as palladium, platinum, or rare earth oxides for auxiliary oxidation. — 3. SCR (Selective Catalytic Reduction) Working Principle • Main function: Reduces NOx (nitrogen oxides) in the exhaust gas to N₂ and H₂O. • Reducing agent used: Urea solution (DEF/AdBlue, mainly CO(NH₂)₂) • Chemical reactions: • 4NO + 4NH₃ + O₂ → 4N₂ + 6H₂O • 6NO₂ + 8NH₃ → 7N₂ + 12H₂O • SCR is usually located after the DPF to ensure good atomization and reaction efficiency of the urea. Materials • Carrier material: • Ceramic honeycomb (usually Al₂O₃-based carrier) or metal honeycomb. • Coating layer: • Catalytically active metals: V₂O₅ (vanadium pentoxide) + WO₃/MoO₃ + TiO₂ • V₂O₅: High activity, but the operating temperature is generally 250–450°C. • TiO₂: Carrier and stabilizer, increases surface area, and is high-temperature resistant. • High-temperature SCR may also use precious metal catalysts (such as Pt), but the industrial standard is a metal oxide system.