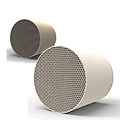

Main Functions of Metal Catalyst Supports

1. Supporting the Active Catalyst Components

• Providing a large surface area, enabling high dispersion of precious metals (such as Pt, Pd, and Rh) or other catalytic components, thereby improving reaction efficiency.

2. Enhancing Thermal Conductivity

• The high thermal conductivity of metals facilitates rapid heat transfer and uniform temperature distribution, reducing the risk of hotspot formation and making them particularly suitable for systems with rapid thermal response, such as cold-start catalysis.

3. Providing Mechanical Strength and Structural Stability

• Withstands high mechanical shock and vibration, making them suitable for high-stress environments such as automotive exhaust systems and industrial reactors.

4. Supporting Complex Structural Design

• Metal materials can be manufactured into complex structures such as honeycomb, foam, or mesh, optimizing airflow distribution and contact efficiency.

5. Strong Thermal Shock Resistance

• Particularly suitable for operating conditions with frequent startups or severe temperature fluctuations. Note: Mesh sizes are 50/100/200/300/400/500/600/700 CPSI.

Maximum temperature: 900°C